How to access your HikVision NVR or Camera on Android devices

Closed-circuit television (CCTV), also known as video surveillance, is the use of video cameras to transmit a signal to a specific place, on a limited set of monitors. It differs from broadcast television in that the signal is not openly transmitted, though it may employ point-to-point (P2P), point-to-multipoint (P2MP), or mesh wired or wireless links but transmit a signal to a specific place only. Not for open to all. This article I write just for HikVision Lover only. Personally I am not support to install Hikvision/Dahua product or OEMN product. Technically 100% unsafe your personal video data.

Day by Day increase hacking of video surveillance camera. Now cyberattacks on CCTV systems making news headlines on a weekly basis of late, there is a good deal of concern and uncertainty about how at risk these systems are, as well as why they are being attacked.

In 2014, a US ally observed a malicious actor attacking the US State Department computer systems. In response the NSA traced the attacker’s source and infiltrated their computer systems gaining access to their CCTV cameras from where they were able to observe the hackers’ comings and goings.

In October 2016, 600,000 internet connected cameras, DVR’s, routers and other IoT devices were compromised and used to for a massive Bot Net to launch what was the largest Denial of Service (DOS) attack the internet had experienced to date.

In the lead up to the 2017 US Presidential inauguration, 65 per cent of the recording servers for the city of Washington CCTV system were infected with ransomware. How did the attack take place? Whilst unknown, it most likely occurred by the same means as other common PC hacks such as infected USB keys, malicious web sites, or phishing attacks.

May, 2018, over 60 Canon cameras in Japan were hacked with “I’m Hacked. bye2” appearing in the camera display text. How did the attack take place? Simple. IP cameras were connected to the internet and were left on default credentials. It appears that the hackers logged into the cameras and changed the on-screen display. What was the impact? Other the defacement of the camera displays and some reputational damage, there doesn’t seem to have been much impact from these attacks.

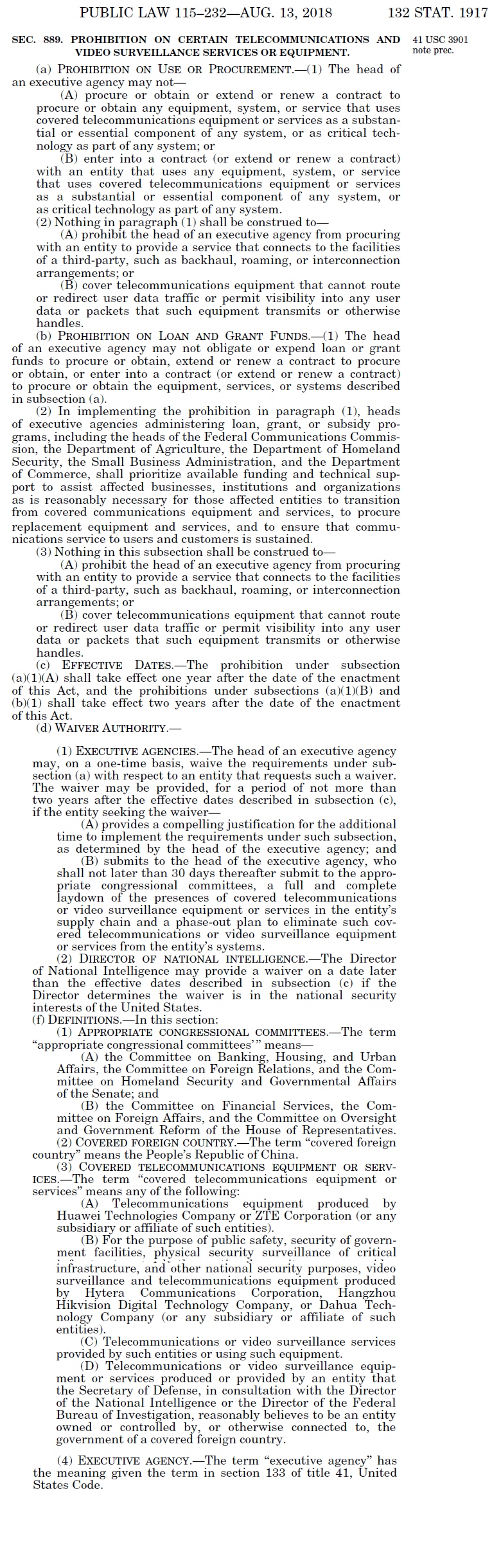

On Aug 13, 2018,

The US President has signed the 2019 NDAA into law, banning the use of

Dahua and HikVision (and their OEMs) for the US government, for US

government-funded contracts and possibly for 'critical infrastructure' and

'national Security’ usage.

US government is

effectively blacklisting Dahua and HikVision products, this will have a severe

branding and consequentially purchasing impact. Many buyers will be concerned

about:

What security risks

those products pose for them

What problems might

occur if they want to integrate with public / government systems

What future legislation at the state or local level might ban usage of such systems

On Jun 06, 2019 Hanwha Techwin is dropping Huawei Hisilicon from all of their products. Its belongs to China’s origin. Backdoor entry is open on product.

China's Wuhan Institute of Virology, the lab at the core of coronavirus. The institute is home to the China Centre for Virus Culture Collection, the largest virus bank in Asia which preserves more than 1,500 strains ( https://www.livemint.com/news/world/china-s-wuhan-institute-of-virology-the-lab-at-the-core-of-a-virus-controversy-11587266870143.html ). Result Corona has infected people in 185 countries. Its spread has left businesses around the world counting the costs. Global economy impact. Recession increase. Now people avoid to get china factory made product, electronics goods importing has stopped from china to other country. People looking for product except china. Now come to Video surveillance, access control equipment.

The ban that

prohibits the purchase and installation of video surveillance equipment from

Hikvision, Dahua and Hytera Communications in federal installations – passed on

year 2018 National Defense Authorization Act (NDAA). In conjunction with the

ban’s implementation, the government has also published a Federal

Acquisition Regulation (FAR) that outlines interim rules for how it will

be applied moving forward. Like NFPA, now NDAA law accept globally.

Rules outlined in

this FAR include:

- A

“solicitation provision” that requires government contractors to declare

whether a bid includes covered equipment under the act;

- Defines

covered equipment to include commercial items, including commercially

available off-the-shelf (COTS) items, which the rule says, “may have a

significant economic impact on a substantial number of small entities;”

- Requires

government procurement officers to modify indefinite delivery contracts to

include the FAR clause for future orders;

- Extends

the ban to contracts at or below both the Micro-Purchase Threshold

($10,000) and Simplified Acquisition Threshold ($250,000), which typically

gives agencies the ability to make purchases without federal acquisition

rules applying.

- Prohibits

the purchase and installation of equipment from Chinese telecom giants

Huawei and ZTE Corporation. This would also presumably extend to Huawei

subsidiary Hisilicon, whose chips are found in many network cameras;

- And, gives executive agency heads the ability grant a one-time waiver on a case-by-case basis for up to a two-year period.

Specifically, NDAA Section

889 creates a general prohibition on telecommunications or video

surveillance equipment or services produced or provided by the following

companies (and associated subsidiaries or affiliates):

- Huawei

Technologies Company; or

- ZTE

Corporation

It also prohibits

equipment or services used specifically for national security

purposes, such as public safety or security of government facilities,

provided by the following companies (and associated subsidiaries or

affiliates):

- Hytera

Communications Corporation;

- Hangzhou

Hikvision Digital Technology Company; or

- Dahua

Technology Company

While the prohibitions

are initially limited to the five named companies, Section 889 authorizes the

Secretary of Defense, in consultation with the Director of National

Intelligence or the Director of the FBI, to extend these restrictions to

additional companies based on their relationships to the Chinese Government.

The prohibitions will take effect for executive-branch agencies on August 13,

2019, one year after the date of the enactment of the 2019 NDAA, and will

extend to beneficiaries of any grants, loans, or subsidies from such agencies

after an additional year.

The provisions of Section 889 are quite broad, and key concepts are left undefined, such as how the Secretary of Defense is to determine what constitutes an entity that is “owned or controlled by, or otherwise connected to” a covered foreign country, or how the head of an agency should determine whether a component is “substantial,” “essential,” or “critical” to the system of which it is part. The statute also fails to address the application of the prohibitions to equipment produced by U.S. manufacturers that incorporate elements supplied by the covered entities as original equipment manufacturers (“OEMs”) or other kinds of supplier relationships.

Section 889 contains

two exceptions under which its prohibitions do not apply:

(1) It allows

Executive agencies to procure services that connect to the facilities of a

third party, “such as backhaul, roaming, or interconnection arrangements.” This

likely means telecommunications providers are permitted to maintain common

network arrangements with the covered entities.

(2) It permits covered telecommunications equipment that is unable to “route or redirect user data traffic or permit visibility into any user data or packets” it might handle, meaning a contractor may still be able to provide services to the Government so long as any covered equipment provided is unable to interact or access the data it handles.

- click

start > control panel

- click

network and internet

- Click

network sharing center

- click

Local area Connection

- Look

at your IPv4 Default Gateway, it is usually either 192.168.1.1 or

192.168.0.1, however it can differ.

Once all this is set up, your cameras or NVR will be properly configured with your Local Network. You should be able to go into your browser and type in the IP address of the camera/NVR, and it will come up with a log in page.

Getting everything to work in the app