LiDAR based Motion Detection Technology

White

light comprises every color of the visible spectrum, with multiple colors

having different frequencies and wavelengths. As a result, it's very

challenging to beam this type of light onto a single point. LEDs commonly

utilized for visual indication in electronic devices and equipment generate

light containing electromagnetic waves of varying frequencies.

Laser

diodes (LDs), on the other hand, produce "coherent light," which

consists of a focused light beam of a specific frequency and wavelength. Their

unique properties make them highly useful in today’s fast-changing world.

LDs are semiconductor devices similar in function to LEDs, but capable of producing coherent laser light. LEDs generate light via electroluminescence — the process of passing an electric current through the device to create photons by creating excess electron and hole pairs. LDs, on the other hand, amplify visible light via stimulated emission of radiation.

Laser light has the following distinct properties:

Coherence: Laser light can be termed coherent since the

wavelength of the light waves emitted is in phase.

High-power and

Intensity: Laser is incredibly bright since it is emitted by continuous

emissions with more power per unit surface area.

Monochromaticity: Laser comprises light waves of

a single wavelength.

Directionality: Light emitted from laser diodes is highly directional, as it shows minimal divergence.

Laser diodes are designed by doping semiconductor materials like aluminum gallium arsenide to create n-type and p-type layers. Doping is the process of adding small amounts of impurities to pure semiconductors to improve conductivity.

LDs give off light when electric current applied to

the device causes the holes and electrons in a semiconductor material to

interact at the p-n junction, also known as stimulated emission. They can also

accurately measure an object’s shape and distance by taking advantage of the

laser beam’s linearity. This technology is known as Light Detection and Ranging

(LiDAR).

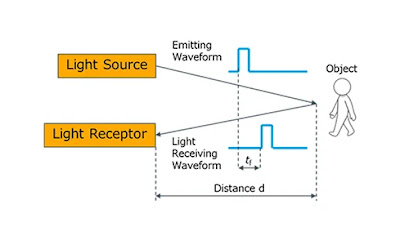

The time of flight (ToF) method is the most used distance measurement method in LiDAR. In the ToF method as depicted in the image below, distance is calculated by measuring the time it takes for the light emitted from the light source to be reflected by the object and returned to the detector (flight time).

LiDAR

follows a simple principle — throw laser light at an object on the earth

surface and calculate the time it takes to return to the LiDAR source. Given

the speed at which the light travels (approximately 186,000 miles per second),

the process of measuring the exact distance through LiDAR appears to be

incredibly fast. However, it’s very technical. The formula that analysts use to

arrive at the precise distance of the object is as follows:

The distance of the object = (Speed of Light x Time of Flight)/ 2

Motion detectors have long been key tools in a security designer’s & customers. Some of devices / detector gives nuisance alarms and installer frustration. The first motion sensor was invented in the 1940s by Samuel Bagno using technology developed during World War II. Using his military knowledge of radar, Bagno developed a device that used ultrasonic waves and the Doppler Effect to detect motion. By the 1970s, these motion detectors were popular components in home burglar alarm systems; however, they were prone to false alarms, as the ultrasonic waves could easily be disrupted by innocent disruptors such as wind or a clock chime.

In the 1980s, advancements in technology brought us the infrared motion sensor. Active infrared sensors work by emitting infrared radiation, detecting differences in temperature between an object and its surroundings. Many motion detectors combine multiple technologies to reduce false alarms. Passive infrared, for example, is commonly paired with microwave detection. Both sensors should be activated before an alarm is triggered.

Fast-forward to today, and companies at the forefront of motion detection have been implementing a new technology: Light Detection and Ranging (LiDAR). Popularized by the autonomous vehicle industry and smartphone manufacturers, LiDAR uses a pulsed laser to calculate the distance from the laser source to an object. By measuring the light from the laser’s reflection, 3-D representations of surfaces can be created. Once a static scene is established, changes to that scene can trigger a motion alarm.

The advantage of LiDAR in this application is how finely the detection area and target object size can be tuned, and how well a target can be tracked. By adding intelligence to how these values are programmed, the days of the security technician “walk test” to determine the detection area may be numbered. LiDAR sensors enhance motion sensor capabilities by providing more detection customization and on-board laser analytics that give you the ability minimize false and nuisance alarms.

The LiDAR sensors themselves have rectangular detection areas, which drastically simplifies design and implementation over traditional fan-shaped detection areas. This enables coverage of large areas with fewer sensors, since they can be placed in locations that eliminate overlap. Rectangular detection areas can be easily used to create detection “planes” along a perimeter, building face or rooftop, for example.

The amount of intelligence built into the device had me wondering whether these motion detectors have jumped categories and are in competition with motion analytics-equipped video surveillance cameras. Motion detectors outperform video analytics because they are purpose-built for the application and have detection technology superior to video cameras. The major value add for using a sensor with a motion detection analytic is to create an IP video double knock.

Motion sensors can transmit coordinate data to integrated video management platforms to help direct cameras to track a target. Because visible light is not a requirement, they can help track targets in darkness, in conditions when a video surveillance camera may be challenged. If a camera is not present to help validate the motion detector alarm, the device itself can store a snapshot of the alarm-inducing condition for retrieval by a security operator.

With motion detectors joining the evergrowing Internet of Things (IoT), ensuring the devices have the appropriate level of cyber features must be considered.

https://en.wikipedia.org/wiki/Lidar

https://www.neonscience.org/resources/learning-hub/tutorials/lidar-basics

https://www.optex.co.jp/e/products/intrusion-detection/redwall/