Why UL listing important

Standards are all around us, even if we are not always aware of them. One example of a widely-used standard is the A4 size for sheets of paper.

A standard is a document that sets out requirements for a specific item, material, component, system or service, or describes in detail a particular method or procedure. Standards facilitate international trade by ensuring compatibility and interoperability of components, products and services. They bring benefits to businesses and consumers in terms of reducing costs, enhancing performance and improving safety.

Standards are developed and defined through a process of sharing knowledge and building consensus among technical experts nominated by interested parties and other stakeholders - including businesses, consumers and environmental groups, among others.

“UL” is short for Underwriters Laboratories, an organization which has been testing and approving products for consumer safety since 1894. Originally known as the Underwriters Electrical Bureau, UL was founded in Chicago by William Merrill, and has since expanded to include 182 service centers in more than 70 countries. Underwriters Laboratories performs safety testing on 18,750 categories of electrical, mechanical and chemical products. So, UL a third-party certification company that’s been around for over a century.

When it comes to UL certification. Certifying products within your business can get expensive, fast. However, one thing that’s never worth skimping on is safety. Your customers’ and workforce’s safety are the most important thing to ensure brand loyalty. Safety and reliability can be the difference between long-term success and catastrophic failure.

UL markers are most commonly seen on industrial equipment and home appliances. These include furnaces, fuses, electrical panels, fire control panel, circuit breakers, cameras, smoke and CO2 alarms, fire extinguishers, sprinklers, glass, and thousands of low voltage equipment. UL Listing in this case means that the product is compliant with the American National Electrical Code (NEC), and is therefore regarded as "safe", i.e., not prone to electrical faults or failures which may cause damage to equipment, facilities, or people.

If your surveillance or safety equipment is not UL listed, it can be ripped out. Technically speaking, cameras and other low-voltage devices do not require UL listing, as they fall under the limited power source (LPS) category. Products in this category do not require listing themselves. Instead, the power source, whether it be a low-voltage supply, midspan, or PoE switch, is to be listed. In practice, however, inspectors often do not follow this, requiring the UL mark other products, as well.

In the surveillance industry, UL listing varies. Many mainstream brands are UL listed. However, it may not apply to every camera in their portfolio, with some lower-cost or SMB/SOHO product being unlisted. Others have only listed the current generations of their equipment. Finally, many lower-cost brands are completely unlisted, limiting their use in some jurisdictions. Users should be aware of these variances when selecting product, and make no assumptions.

In the safety industry, UL listing must be in Detector, Fire Control Panel, MCP, Module, sprinkler, Pump etc. Some OEM follow EN listing of said item for safety i.e., not prone to electrical faults or failures which may cause damage to equipment, facilities, or people.

Listing can generally be found on data sheets, normally in an "approvals" section, though not always. Sometimes it is found only in installation manuals, and other times users must contact the company to get listing information. All these variables make UL compliance a tedious process.

While 'UL Certification' implies electrical safety, the actual standard number it satisfies varies.

For surveillance gear, there are below certification standards that address different safety aspects:

- UL 60950: Is the most common for cameras, and applies to low voltage safety (ie: non combustibility)

- UL 1492: Audio/Video Products and Accessories

- UL 1995: Heating and Cooling Equipment

- UL 2802: Tests related to performance quality of Camera image quality.

- UL 2043: Standard for Fire Test for Heat and Visible Smoke Release for Discrete Products and Their Accessories Installed in Air-Handling Spaces.

- UL 60065: Audio, Video and Similar Electronic Apparatuses: Safety Requirements.

- UL 325: Safety standard for door, drapery, gate, louver, and window operators and systems. Specifically, it applies to electric operators for doors, draperies, gates, louvers, windows and other opening and closing appliances rated 600 volts or less.

For Life Safety gear, there are below certification standards that address different safety aspects:

· UL 217: Single- and Multiple- Station Smoke Alarms

· UL 268: Smoke Detectors for Fire Protective Signalling Systems

· UL 268A: Smoke Detectors for Duct Application

· UL 294: Standard for Access Control System Units

· UL 1023: Standard for Household Burglar-Alarm System Units

· UL 1610: Standard for Central-Station Burglar-Alarm Units

· UL 864: Standard for Control Units and Accessories for Fire Alarm Systems

· UL 1626: Residential Sprinklers for Fire Protection Service

· UL 1971: Signalling Devices for the Hearing Impaired

· UL 1741: Inverters, Converters, Controllers and Interconnection System Equipment for Use with Distributed Energy Resources

For Wire and Cable gear, there are below certification standards that address different safety aspects:

· UL 62: Flexible Cords and Cables

· UL 758: Appliance Wiring Material (AWM)

· UL 817: Cord Sets and Power Supply Cords

· UL 2556: Wire and Cable Test Methods

Someone is shopping for a new circuit breaker or contactor; UL certification might sway their decision. If two identical products or services are side-by-side and one is UL certified and one isn’t, which one would you likely choose? It’s been shown that the UL mark can be a powerful marketing tool for businesses, and so many of them strive to get their products approved. The UL logo gives the consumer peace of mind, and the business a public seal of approval.

Whether the UL mark is required on all electrical parts in an installation varies tremendously, depending on the municipality, and even between different inspectors. We have seen various requirements for listing, in different municipalities:

- No UL listing required: Some municipalities are extremely lenient, never checking any product for UL certification.

- Ceiling-mounted products: One of the most arbitrary requirements we have seen is that all ceiling-mounted equipment must be listed, but no other parts of the system were checked.

- High-voltage only: In other cases, only high-voltage products require UL listing. This means that electricians are required to comply, but low-voltage security equipment is exempt.

- Strict, 100% listing: In the most extreme cases, the building inspector will require every last part of an installation to bear the UL mark, whether it be servers, cameras, cable, or any other components.

These variations, and others, are why we suggest users should check with their AHJ before installation. In some cases, bids and RFPs may also provide requirements for UL certification, taking the guesswork out of the process.

Since the level of compliance required may vary significantly, it is recommended that users check requirements with the authority having jurisdiction before installation takes place, or even before furnishing estimates.

If unlisted products are being used, but the inspector requires certification, users have two options:

- Replace the non-compliant product with compliant. This is often the simplest way to gain compliance. The major downside is, of course, that product must be removed and replaced, incurring additional material, shipping, and labor costs.

- Contract UL to provide a one-time certification of the system of the whole. In this case, a UL engineer visits the site and performs testing of the system in place. While this may alleviate listing issues, it is extremely expensive, commonly in the $10,000+ range for even small installations. It is therefore considered a last resort.

UL Certification allows a company to innovate its safety standards and align themselves with industry-wide best practices. Being UL certified illustrates a businesses’ dedication to consumer safety, as well as the quality of their products. Another important caveat of UL certification is for insurance purposes and customer security.

Why is this important? If, say, an inspector determines a fire was caused by a circuit breaker that was not UL certified, an insurance company can choose to deny the claim. For this reason alone, many consumers opt for certified products, not just for large appliances but for small ones as well as laptop and cell phone chargers. UL certification adds a layer of protection and accountability for accidents, as well. UL is a third-party service; consumers of your products can be confident that the UL seal is not a superficial sales ploy. Instead, it’s a true indication of an item’s safety and longevity. It protects brand’s reputation by having an established certification company standing behind what you sell. Remember if you use UL product due to some malfunction you decided to repair your device / panel. Then you must involve said product OEM/ authorised professional. Do not repair through technician / engineer / repairing centre, if you do then UL listing is void. It assumed as zero safety. In case further malfunction or electrical hazard happened then OEM are not responsible for it.

So, don’t immediately assume your products aren’t safe just because it doesn’t have a UL certification. It’s never a bad idea, however, to seek out UL certification when designing into new electronics and appliances.

Even if it might cost a bit more for your business or take extra testing time, UL gives a consumer the peace of mind and a brand a big marketing boost. In the long run, third-party certifications from a trusted source will only help your business. UL Certifications have the ability to add accountability and enhance your brand’s reputation over time.

UL certification provides third-party Verification that the video monitoring services being provided are compliant with industry requirements, giving subscribers a new level of confidence.Qualified monitoring stations will undergo an audit during each calendar year by our audit staff in order to verify continued compliance. Such audits will assess both the monitoring station facility and the delivery of services to subscribers who have been issued UL monitoring certificates.

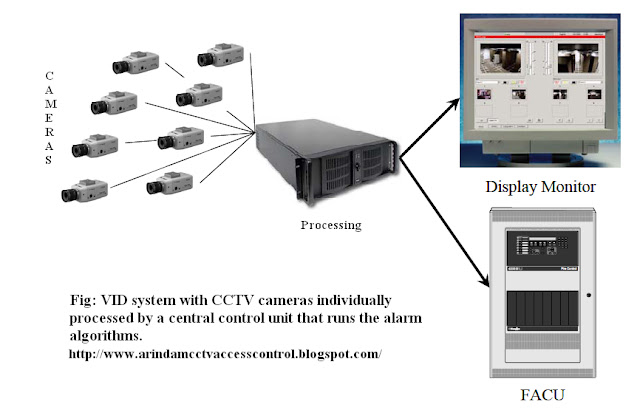

The managed video service provider has personnel located at a managed video monitoring station in order to:

- View video streams

- Make informed decisions

- Interact with people or systems at a protected property

- Notify identified parties of events

Hopefully, now you feel a bit more familiar with that little UL logo and have a better idea of what it means and why it’s important for you and your business. When manufacturers are UL certified is shows their continued commitment to safety and quality.

Ready to upgrade your home or workplace with UL certified parts and products? Shop our full assortment of devices, switches, and other electronics.

Ref: