System

integrator role in SSA Business

Yam,

you know SSA is stands for Security Safety Automation (SSA Integrate). A security systems

integrator by definition specializes in bringing together subsystems into a

whole and ensuring that those subsystems function together. When the goal is

physical security, those subsystems might be Video surveillance, Access

control, Intrusion, FDA or Emergency notification, BAS, computer networks and

more. Some security suppliers have established business simply on the

procurement and installation of systems predefined by others. More fully

developed are considered ‘design-build’ integrators. However the most capable

security integrator is a full service provider capable of supporting your

operations in every phase of the security system lifecycle:

1. Security risk or needs assessments,

2. System engineering and design for

the major technologies,

3. Broad access to the leading product

lines,

4. Custom engineering when required,

5. Alternate investment options,

6. Procurement, staging, installation,

commissioning and training,

7. Full lifecycle service and

maintenance,

8. System functional and technology

upgrades.

A

client who selects an integrator fully capable in all the above can then take

advantage of his unique perspective on what are the key ingredients for

successful development of a physical security program that is supportive of a

healthy enterprise.

Working

with a full service security provider also reinforces quality. Consider why

this is so. If, for instance, the integrator offers long term service and

maintenance for the system he installs, then both the service provider and the

customer are motivated that the design should be solid and the installation of

high quality. And if the integrator can offer attractive long term financing,

even operational leases, then he again has a further stake in the caliber of

the security provided.

System integration is defined in engineering as the process of bringing together the component sub-systems into one system (an aggregation of subsystems cooperating so that the system is able to deliver the overarching functionality) and ensuring that the subsystems function together as a system, and in information technology as the process of linking together different computing systems and software applications physically or functionally, to act as a coordinated whole.

System integration is defined in engineering as the process of bringing together the component sub-systems into one system (an aggregation of subsystems cooperating so that the system is able to deliver the overarching functionality) and ensuring that the subsystems function together as a system, and in information technology as the process of linking together different computing systems and software applications physically or functionally, to act as a coordinated whole.

System

Integrators in the automation industry typically provide the product and

application experience in implementing complex automation solutions. Often,

System Integrators are aligned with automation vendors, joining their various

System Integrator programs for access to development products, resources and

technical support. System integrators are tightly linked to their accounts and

often are viewed as the engineering departments for small manufacturers,

handling their automation system installation, commissioning and long term

maintenance.

Are there tangible ways that we see

interoperability trending in the industry?

There is certainly movement toward

standard-compliant products but it is slow. I attribute this mainly due to

engineers reusing portions of old or outdated specs along with their lack of

knowledge of the current product offerings. IP cameras will help move the

standards along since more and more clients are aware of megapixel technology

and it forces the engineers to become more current.

Where do you see underserved or untapped

opportunities for security systems integrators to provide integration and

automation expertise?

Video

and access technology have the potential to be integrated well beyond the

traditional Big Brother stereotype applications. One example is warehouse distribution

and processing applications where repetitive tasks performed incorrectly can

slow production or cause injuries. Video analytics could be modified to monitor

physical movement and monitor improper technique that could lead to injuries.

These

videos could initiate notifications to HR and management staff to alert them to

potential problems before they occur. Access to machines and forklifts could be

controlled through HR records. Integrating the access system to training and

safety certifications could help reduce unqualified employees from accessing

and enabling critical operational systems. Security could monitor the

traditional video footage, HR could assemble incident reports tagged with the

video and management could build and expand training programs with real world

examples.

Another area of potential growth is

the smart building. A fully integrated structure including security, lighting, HVAC

and building controls that provides a return on investment along with the

ability to remotely manage a site.

How can a locally-based or small regional

company have successes in enterprise-level organizations?

Local

companies can have a distinct advantage over the national integrators. First,

the small or regional company must be technically advanced and focused on

cutting-edge technology so they can provide a value to an enterprise-level

client. They must also network with similar dealers with related product lines

so they can establish an installation network throughout North America or the

regions they are required to service. They can also become an agent for the

enterprise client and coordinate all installations and manage that system for

that client. Compare that level of service to the big integrators. Yes, they

have a handful of talented individuals that truly get the big picture and these

men and women travel the country and the world implementing systems. But once

the job is completed, they’re off to the next one and you may never see them

again.

How can smaller integrators differentiate to

better compete?

A commitment to service is the local integrators greatest

strength. Through continuing education of its technical staff and building

working relationships with clients, a local integrator can react quickly and

see the big picture of their customers’ needs and requests. As the IT

department begins to dominate the physical security industry the local

integrator can help be a bridge between the security professionals and the

sometimes frustrating “smartest man in the room” syndrome of the IT staff .

Most integrators have a great respect for the current and former local and

national law enforcement professionals we work with every day. Their knowledge

of where and why a camera is placed and how to implement the concentric rings

of security, lighting control and placement is invaluable. The human element of

security beyond pure technology is something that some IT professionals do not

always grasp. Integrators can successful bridging that gap when they strive to

clearly communicate with both departments.

What is the Solution Development Process With

a Full Service Systems Integrator?

Risk Assessment. Your integrator should be

able to assist or guide you in this first step toward development of a security

solution. The industry standard for this is the ASIS 7-step general security

risk assessment guideline. The guideline defines a process which starts with

identification of assets and risk events and ends with a solution cost benefit

analysis. Properly done the end product is not only the security you want and

need but a documented rationale for the investment.

Financial

Options. Similar to many

internal enterprise processes the best electronic security solution is

sometimes planned to be phased-in over time to give the client the best

possible security function progressively. Nonetheless a full service integrator

enables you to tailor acquisition of enhanced security in a manner which meets

your needs. As an example, reasonably priced capital leases can push the cash

flow impact of security into outer years. Due to current accelerated tax

depreciation in effect these leases can in some instances reduce the net cost

below that of an outright purchase. If a full service integrator has the

internal resources – service fleet, repair department, stocked inventory, etc.

– to maintain their installed systems they may also offer and administer

operational lease programs to the security solutions they provide. These leases

differ from capital leases in that ownership of the physical security equipment

is retained by the service provider yet the site installation and its sustained

operability is available as a monthly service fee.

Design. The functional design should clearly

define for the end user the extent of the solution’s protection. It may involve

multiple technologies for the most effective solution. Minimizing the burden

placed on general staff to maintain security and respond to emergencies should

typically be a demonstrable objective.

Value

driven component selection may require a number of different supplier sources.

Exterior components will be weatherproof, interior components will be vandal

and wear resistant as needed. System operation will be well protected from the

dangers of tampering, surges, electrical strikes, etc. as well as single points

of failure if possible. A good design will not dead-end the customer but

position the delivered security solution for adaptation to meet anticipated

future needs. Good designs may even enhance as well as protect enterprise and

site operations.

Installation &

Commissioning. The installation should

conform to and even exceed state and federal regulations and guidelines and be

performed by licensed personnel as required. The installation should be safe

for all onsite, reflect excellent workmanship and conduct should be courteous

and respectful to all involved. System configuration should be performed by

individuals with good system knowledge. The end user training should be

complete enough to address at least typical daily tasks and provide them the

resources they need to reinforce the training and administer further if

required. This is most likely provided by a resource positioned to be a partner

in meeting your security needs.

System Maintenance and

Service. The overarching goal is

to maintain the operability of your security solution with the same

effectiveness experienced as it was commissioned. But electronics degrade and

fail and sites often continuously require system tweaks as they grow. A good

service program will make available to you certified service personnel as well

as standard and emergency response times you can depend on. The best providers

will often maintain stock for repair and loan and even have in house bench

repair capability for rapid, cost effective turn around. And if you have

outgrown your security systems or they are generally showing their age a good

provider can offer mid-life upgrades and/or ‘system refreshes’ which

progressively secure your operations and people.

Enterprise Security is Not A

Commodity.

Why

is enterprise physical electronic security more than just a commodity to be

procured? Because the security risks are multiple, varied and changing. Some

which occur infrequently are the most potentially damaging. An outside

perspective developed from meeting a variety of client needs can help prioritize.

The current solution state of the art is technical, multidisciplinary and

rapidly evolving. There is not a consumer protected design-bid-build process

which guarantees success. Only a subset of security industry service providers

are equipped and positioned to reliably assist you from needs development

through to system maintenance.

Trust on your selective System Integrator or Solution Service Provider.

System Integrator who really work in different system with different brand system, they are know who or which OEM has good service support. No one integrator is wise for all product. System Integrator surve customer. OEM will not provide service.

Trust on your selective System Integrator or Solution Service Provider.

System Integrator who really work in different system with different brand system, they are know who or which OEM has good service support. No one integrator is wise for all product. System Integrator surve customer. OEM will not provide service.

Tips to choose Best System Integrator in India

·

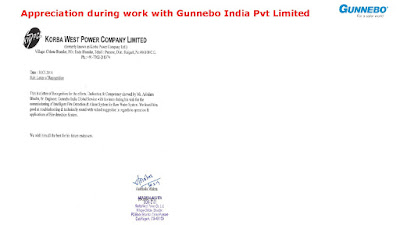

Choose

a systems integrator who has a list of successful projects with appreciation letter

from customer. Check references, talk to their clients and take reviews. Find

out for how long they have been in the field.

·

System

Integrator should have long-term relationship and close ties with the leading

OEMs. These relationships allow an integrator to keep up to date on new

technologies, get the best prices, and provide you with the most complete

support network available. The best integrators focus on customer needs and

build solutions using best of breed technologies. They should have a broad

range of products they have worked with and enough staff to handle different

areas of the project.

·

The

integrator should prove that they understood your requirements. Take Quote from

multiple System Integrators. Be especially careful if you get lower price than

expected or that others have quoted. Make sure the system integrator doesn’t

over commit during negotiations.

·

System

Integrator should have specialized expertise and that can be applied

to create an architecture that ensures security, flexibility, and scalability

to meet your IT service availability demands. Focus on their knowledge,

techniques and skills. Make sure they have full knowledge of system engineering,

as well as sufficient experience to handle your project.

·

If

you don’t have in-house expertise for making the integrator selection, consider

hiring a third-party technical consultant to establish selection criteria

and/or participate in the review process. Get involved at the zero level in the

planning, simulation, detailed layout, software handling techniques and

maintenance requirements as much as you possibly can in order to get the

biggest possible benefits. In this point our Writer can help, you may connect

with this article writer.

·

Keep

up-to-date milestone records during the course of the project. If you have to

replace an integrator, refer to the specification and decide on a fair

settlement covering payment for all completed deliverables. System Integrator

should have a knowledge transfer process in place. This ensures you have the

time and resources necessary to ensure your team understands the work product

and can continue on – independently and successfully.

·

Look

for an integrator that listens to your needs, communicates well, and provides

customized solutions for your business.

·

Select

an integrator that has a large, experienced engineering core with a holistic

understanding of your entire ELV ecosystem. This will facilitate better

design, deployment and support.

·

System

Integrator 2/3 team member should have Membership their own technology field like:

ASIS International, SIA (SECURITY INDUSTRY ASSOCIATION), FSAI, National Safety

Council.

For a Free

Consultation Call: +919903280406

Please find below my details.