GUIDE TO BUILDING AUTOMATION

Building automation is monitoring and controlling a

building’s systems including: mechanical, security, fire safety, lighting,

heating, ventilation, and air conditioning.

Such systems can

- ·

keep

building climates within a specified range,

- ·

light

rooms according to an occupancy schedule,

- ·

monitor

performance and device failures in all systems, and

- ·

alarm

facility managers in the event of a malfunction.

Relative to a non-controlled building, a building with

a BAS has lower energy and maintenance costs.

There are many components to a building automation

system that require a little explaining to understand, and the benefits of

installing such a system may not be immediately clear until you understand the

mechanisms driving these systems.

That’s why we created this ultimate guide to

understanding building automation systems. It’s designed to be an easy

read-through, but feel free to use the links below to go directly to a topic

that is relevant to your own research.

WHAT

IS BUILDING AUTOMATION?

Building automation most broadly

refers to creating centralized, networked systems of hardware and software

monitors and controls a building’s facility systems (electricity, lighting,

plumbing, HVAC, water supply, etc.)

When facilities are monitored and

controlled in a seamless fashion, this creates a much more reliable working

environment for the building’s tenants. Furthermore, the efficiency introduced

through automation allows the building’s facility management team to adopt more

sustainable practices and reduce energy costs.

These are the four core functions of

a building automation system:

·

To

control the building environment

·

To

operate systems according to occupancy and energy demand

·

To

monitor and correct system performance

·

To

alert or sound alarms when needed

At optimal performance levels, an

automated building is greener and more user-friendly than a non-controlled

building.

A Building Automation System may be denoted as:

An automated system where building services, such as utilities, communicate with each other to exchange digital, analogue or other forms of information, potentially to a central control point.

An automated system where building services, such as utilities, communicate with each other to exchange digital, analogue or other forms of information, potentially to a central control point.

What Is Meant By ‘Controlled?

A

key component in a building automation system is called a controller, which is

a small, specialized computer. We will explore exactly how these work in a

later section. For now, it’s important to understand the applications of these

controllers.

Controllers

regulate the performance of various facilities within the building. Traditionally,

this includes the following:

·

Mechanical

systems

·

Electrical

systems

·

Plumbing

systems

·

Heating,

ventilation and air-conditioning systems

·

Lighting

systems

·

Security

Systems

·

Surveillance

Systems

A

more robust building automation system can even control security systems, the

fire alarm system and the building’s elevators.

To

understand the importance of control, it helps to imagine a much older system,

such as an old heating system. Take wood-burning stoves, for example. Anyone

heating their buildings through pure woodfire had no way to precisely regulate

the temperature, or even the smoke output. Furthermore, fueling that fire was a

manual effort.

Fast-forward

150 years: Heating systems can be regulated with intelligent controllers that

can set the temperature of a specific room to a precise degree. And it can be

set to automatically cool down overnight, when no one is in the building.

The

technology that exists today allows buildings to essentially learn from itself.

A modern building automation system will monitor the various facilities it

controls to understand how to optimize for maximum efficiency. It’s no longer a

matter of heating a room to a specific temperature; systems today can learn who

enters what rooms at what times so that buildings can adjust to the needs of

the tenants, and then conserve energy when none is needed.

There

is a growing overlap between the idea of controlling a building and learning

from all the data the system collects. That’s why automated buildings are

called “smart buildings” or “intelligent buildings.” And they’re getting

smarter all the time.

THE

EVOLUTION OF SMART BUILDINGS

Kevin Callahan, writing for

Automation.com, points to the creation of the incubator thermostat — to keep

chicken eggs warm and allow them to hatch — as the origin of smart buildings.

Like most technologies, building

automation has advanced just within our lifetimes at a rate that would have

baffled facility managers and engineers in, say, the 1950s. Back then,

automated buildings relied on pneumatic controls in which compressed air was

the medium of exchange for the monitors and controllers in the system.

By the 1980s, microprocessors had

become small enough and sufficiently inexpensive that they could be implemented

in building automation systems. Moving from compressed air to analog controls

to digital controls was nothing short of a revolution. A decade later, open

protocols were introduced that allowed the controlled facilities to actually

communicate with one another. By the turn of the millennium, wireless

technology allowed components to communicate without cable attachments.

An

Intelligent Building system may be denoted as:

An automated system where building services and corporate

processes, communicate with each other to exchange digital, analogue or other

forms of information, to a central control point to manage the environment.

Terms to Understand

At first, the terms building

automation professionals use look like a big game of alphabet soup. There are

acronyms everywhere. Let’s clarify this now:

Building Management

System (BMS) and Building Control System (BCS) — These are more general terms

for systems that control a building’s facilities, although they are not

necessarily automation systems.

Building Automation

System (BAS) —

A BAS is a subset of the management and control systems above and can be a part

of the larger BMS or BCS. That said, building management and building

automation have so thoroughly overlapped in recent years that it’s

understandable people would use those terms interchangeably.

Energy Management

System (EMS) and Energy Management Control System (EMCS)— These are systems that

specifically deal with energy consumption, metering, etc. There is enough

overlap between what a BAS does and what an EMS does that we can consider these

synonymous.

Direct Digital Control

(DDC) — This

is the innovation that was brought about by small, affordable microprocessors

in the ‘80s. DDC is the method by which the components of a digital system

communicate.

Application

Programming Interface (API) —

This is a term common in computer programing. It describes the code that

defines how two or more pieces of software communicate with one another.

What makes the terminology

particularly complicated is that the technology evolves so quickly that it’s

hard to know at what point a new term needs to be applied. Then, you also have

professionals in different countries using different terms but still having to

communicate with one another. Just be prepared for the terminology to be in a

state of flux.

HOW

DO BUILDING AUTOMATION SYSTEMS WORK?

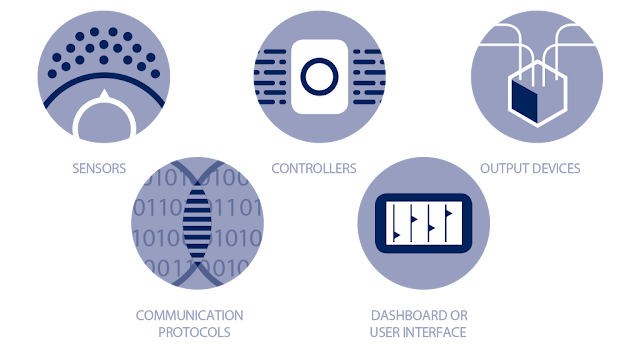

Basic BAS have five essential

components:

Input devices / Sensors — Devices that measure values

such as CO2 output, temperature, humidity, daylight or even room occupancy.

Controllers — These are the brains of the

systems. Controllers take data from the collectors and decide how the system

will respond.

Output devices — These carry out the commands

from the controller. Example devices are relays and actuators.

Communications

protocols —

Think of these as the language spoken among the components of the BAS. A

popular example of a communications protocol is BACnet.

Dashboard or user

interface —

These are the screens or interfaces humans use to interact with the BAS. The

dashboard is where building data are reported.

What a BAS Can Do

·

It

can set up the lighting and HVAC systems to operate on a schedule that makes

those systems both more intelligent and more efficient.

·

It

can get the various components and facilities within a building to coordinate

and work together toward greater overall efficiency.

·

It

can optimize the flow of incoming outside air to regulate freshness,

temperature and comfort inside the building.

·

It

can tell you when an HVAC unit is running in both heating and cooling helping

to reduce utility costs.

·

It

can know when an emergency such as a fire breaks out and turn off any

facilities that could endanger building occupants.

·

It

can detect a problem with one of the building’s facilities — such as, for

example, an elevator getting stuck with people inside — and send an instant

message or an email to the building’s facility manager to alert him/her of the

problem.

·

It

can identify who and when someone is entering and leaving a building

·

It

can turn a camera on a begin recording when activity takes place – and send an

alert and direct camera feed to the security team and facility manager.

·

Are

there other functions that address clear pain points for building owners /

facility managers?

The Role of

Controllers

Controllers are the brains of the

BAS, so they require a little more exploration. As mentioned above, the advent

of direct digital control modules opened up a whole universe of possibilities

for automating buildings.

A digital controller can receive

input data, apply logic (an algorithm, just as Google does with search data) to

that information, then send out a command based on what information was

processed. This is best illustrated through the basic three-part DDC loop:

1. Let’s say a sensor detects an

increase in temperature in a company’s board room when the room is known to be

unoccupied.

2. The controller will apply logic

according to what it knows: That no one is expected in that room, thus there is

no demand for additional heat, thus there is no need for that room to warm up.

(Note: The algorithm with which a controller processes information is actually

far more complex than depicted in this example.) It then sends a command to the

heating system to reduce output.

3. The actual heating unit for the

boardroom in question receives that command and dials back its heat output. All

of this appears to happen almost instantaneously.

WHY

ARE BUILDING AUTOMATION SYSTEMS USEFUL?

The

benefits of building automation are manifold, but the real reasons facility

managers adopt building automation systems break down into three broad

categories:

·

They

save building owners money

·

They

allow building occupants to feel more comfortable and be more productive

·

They

reduce a building’s environmental impact

Saving Money

The place where a BAS can save a

building owner a significant amount of money is in utility bills. A more

energy-efficient building simply costs less to run.

An automated building can, for

example, learn and begin to predict building and room occupancy, as

demonstrated earlier with the heated board room example. If a building can know

when the demand for lighting or HVAC facilities will wax and wane, then it can

dial back output when demand is lower. Estimated energy savings from simply

monitoring occupancy range from 10-30%, which can add up to thousands of

dollars saved on utilities each month.

Furthermore, a building can also

sync up with the outdoor environment for maximum efficiency. This is most

useful during the spring and summer, when there is more daylight (and thus less

demand for interior lighting) and when it is warmer outside, allowing the

building to leverage natural air circulation for comfort.

Data collection and reporting also

makes facility management more cost efficient. In the event of a failure

somewhere within the system, this will get reported right on the BAS dashboard,

meaning a facility professional doesn’t have to spend time looking for and

trying to diagnose the problem.

Finally, optimizing the operations

of different building facilities extends the lives of the actual equipment,

meaning reduced replacement and maintenance costs.

Typically, facility managers find

that the money a BAS saves them will over time offset the installation and

implementation of the system itself.

Comfort and

Productivity

Smarter control over the building’s

internal environment will keep occupants happier, thereby reducing complaints

and time spent resolving those complaints. Furthermore, studies have shown that

improved ventilation and air quality have a direct impact on a business’s bottom

line: Employees take fewer sick days, and greater comfort allows employees to

focus on their work, allowing them to increase their individual productivity.

Environmentally

Friendly

The key to an automated building’s

reduced environmental impact is its energy efficiency. By reducing energy

consumption, a BAS can reduce the output of greenhouse gases and improve the

building’s indoor air quality, the latter of which ties back into bottom-line

concerns about occupant productivity.

Furthermore, an automated building

can monitor and thus control waste in facilities such as the plumbing and

wastewater systems. By reducing waste through efficiencies, a BAS can leave an

even smaller environmental footprint. In addition, a regulatory government

agency could collect the BAS’s data to actually validate a building’s energy

consumption. This is key if the building’s owner is trying to achieve LEED or

some other type of certification.

The fact that everything is integrated into one control

system, instead of three separate systems, is a real positive – Arindam Bhadra,

Technical Head, SSA Integrate.

Sources