Fire safety professionals

constantly seek the benefits of early warning of potential fires. In a perfect

world it would be possible to place hundreds of smoke detecting sensors above

and around any items or areas at risk. This would certainly enable a fast

response to a potential fire, saving valuable time even in voluminous areas or

where a high airflow may be present. But of course such a dream is not possible

from a practical or financial point of view.

Video smoke detection

technology makes this dream a reality.

Video smoke (VISD) and flame detection (VIFD) is performed

by a software algorithm running on Visual Signal Processors (ViSPs) that

implement parallel processing engines in hardware. Video images are analysed in

real time by applying digital image processing techniques that allows smoke and

flames to be detected with a high degree of confidence. The video image is

continually monitored for changes and false alarms are eliminated by

compensating for camera noise and acquiring knowledge of the camera view over

time.

|

| an illustration of how the Video Smoke Detection

process works |

Multiple zones can be defined for a camera view in which

smoke and flames are to be detected. Each zone has a set of parameters that

provide complete control over the detection algorithm. These parameters are

configured individually for each zone in order to cater for a wide variety of

application scenarios. It is also possible to combine information from multiple

cameras to enhance the detection process.

Stemming from many years of research and development several

complex statistical and geometrical measurements are made on the video image

data from each zone as dictated by the control parameters. This is made

possible by the parallel digital signal processing capabilities of the

hardware. The scale of parameter settings is such that it is possible to detect

smoke ranging from slow emerging faint smoke through to dense smoke plumes that

are produced in a short period of time.

Once the measurements have been made from the video image

data a set of rules can be applied to determine if they characterise smoke or

flames. The rules can also be tuned to meet the specific application

requirements to complete a robust and successful detection algorithm.

VSD/VID (VISD) is based on sophisticated computer analysis

of the video image seen by the CCTV camera (sensor). Using advanced

image-processing technology and extensive detection algorithms (and known false

alarm phenomena); the VID can automatically identify the distinctive

characteristics of smoke patterns. The fire detection industry has an abundance

of known smoke signatures and these are built into the system to give an

accurate decision on whether smoke is present.

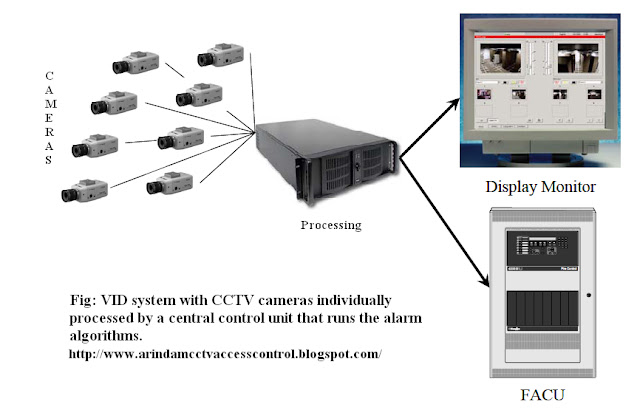

The VSD system uses standard CCTV equipment linked to a self

contained processing system which is capable of recognising small amounts of

smoke within the video image and alerting the system operator both at the

processor and by a variety of remote outputs.

The VSD system employs highly complex algorithms to process

video information from CCTV cameras simultaneously. The video hardware is

designed to allow simultaneous real time digitising of all images, which means

that the system does not multiplex images and, therefore, no information is

lost or delayed. All alarm condition images are logged, time & date

stamped, and stored within the system’s memory.

The VSD system detects smoke rapidly by looking for small

areas of change within the image at the digitisation stage and only passing

these pixel changes to the main processor for further filtering.

The video information is passed through a series of filters,

which seek particular characteristics that can be associated with smoke behavior.

Further analysis is then carried out on the relationships between the filtered

characteristics to determine whether all the conditions have been met for the

system to confidently predict the presence of smoke.

The system installer has the ability to vary the amount of

smoke signal, and the length of time that the smoke exists before an alarm

condition is raised to cater for situations where there may be background smoke

present. The installer may also divide the video image into up to 16 zones and programmed

the system to alarm only if smoke is present in multiple zones. Each zone can

also be separately configured to generate an alarm at different levels of smoke

activity.

The performance of a Smoke or Flame VID system must take

into account three general items:

1. Fire sources

2. Environment

3. System variables

Standard smoke detection systems, be they point detection

systems, infra-red beam detectors or aspirating systems all require the smoke

generated from any combustion to reach them before they can recognise the

particulates and activate an alarm. Such systems can function very effectively

in internal thermally stable environments with low to moderate ceiling heights.

In large volumeous spaces such as enclosed sports arenas,

exhibition halls, aircraft hangers and atriums, solar radiation, air

conditioning systems and translucent glass all contribute to an increasing

ambient temperature from floor to ceiling, known as a thermally stratified

environment.

In a smouldering fire or low energy flaming fire scenario

the raising combustion products cool as they rise through the air and move

further away from the centre of combustion. In a temperature-stratified

environment the ambient air temperature increases with height. As the

combustion plume rises it cools, if this cooling reaches equilibrium with the

temperature of the ambient air the smoke products will loose their buoyancy and

move laterally to produce a roughly horizontal layer. If the temperature

slowly increases the hot air above the smoke will expand thus further reducing

the height of the smoke stratification layer.

In environments with a high percentage change of air caused

by either high velocity air-conditioning (HVAC) systems, or large open doors,

smoke particles generated during low energy combustion can become quickly

dispersed or diluted to the point where there are insufficient concentrations

to activate an alarm in a standard smoke detection system.

These twin problems of stratification and dilution can

seriously delay or even prevent a smoke detection system from entering an alarm

state.

VSD systems over come both of these phenomena by looking

below any stratification or dilution boundary at the incept point of any

potential fire and identifying smoke generation at or very close to the source.

So, be separately configured to generate an alarm at

different levels of smoke activity.

In general, VSD

systems do not have fixed settings. They have many parameters that need to be

adjusted to provide the optimum response to a specific fire risk. Therefore, it

is very important that the manufacturer should be fully consulted in matters of

product application and system design. The manufacturer’s installation,

commissioning and service and maintenance instructions should also be followed.

The location and spacing of detectors shall be based on the

principle of operation and an engineering survey of the conditions anticipated

in service. The manufacturer’s published instructions shall be consulted for

recommended detector uses and locations. an engineering evaluation that

includes the following:

(1) Structural features, size, and shape of the rooms and

bays

(2) Occupancy and uses of the area

(3) Ceiling height

(4) Ceiling shape, surface, and obstructions

(5) Ventilation

(6) Ambient environment

(7) Burning characteristics of the combustible materials

present

(8) Configuration of the contents in the area to be

protected

The National Fire Alarm Code, NFPA 72-2007, recognizes the

use of flame and smoke VID systems. (5.7.6 Video Image Smoke Detection; 5.8.5

Video Image Flame Detection) Per the Code, the installation of these

systems requires a performance-based design. There are no prescriptive sitting

requirements. Flame VID systems are classified as radiant energy sensing fire

detectors and are treated similar to optical flame detectors. Due to the

variability of VISD system capabilities and the differences in alarm algorithm

technologies, NFPA 72 requires that the systems be inspected, tested, and maintained

in accordance with the manufacturer’s published instructions.

Currently, there are no systems that are UL listed, and

there is no UL standard that specifically addresses VID/VSD systems. Four

systems have been FM approved. These include a system that detects only smoke,

one that detects only flame and two that detect both. The systems have been

approved to meet the requirements of FM Standard 3260, Radiant Energy- Sensing

Fire Detectors for Automatic Fire Alarm Signaling, and UL 268, Smoke Detectors

for Fire Alarm Signaling Systems.

The effect of all the changeable parameters in the VSD, such

as camera lenses, software parameters adjustment and lighting conditions should

be taken into consideration following the consultation principle given in BS5839

Part 1: 2002, clause 6.

BS 5839-1:2002 recognises the existence of VSD. Clause 21 j)

recommends that:

"Video smoke detection systems should be capable of

detecting smoke reliably in the absence of the normal lighting in the building

and the absence of the mains power supply to any lighting provided specifically

to aid the detection of smoke."

The foundational information collected for identifying

typical/standard fire and smoke scenarios, likely false/nuisance scenarios, and

a range of ambient conditions to which VISD systems may be subjected in the

three target applications. This work included researching and reviewing fire

incident data and conducting an industry workshop on VISD technology. On-site

surveys and interviews with end-users were also conducted.

Installation cables should be in accordance with the

recommendations of BS 5839-1:2002.

A VSD detecting fires in certain large open areas and areas

of special high risk as:

1. VSD systems can be used for outdoor applications, such as

train stations and off-shore oil platforms.

2. The ability of VSD to be programmed to provide different

sensitivity (range) by lens selection, and to adapt to difficult application

environments (false alarm sources) by tuning software operational parameters,

makes it an ideal detection tool in special applications where an engineered

solution is likely to give the best answer.

3. The ability to protect a large area, and/or areas with

excessive ceiling heights, while still achieving fast detection. With VSD,

smoke in the camera field of view can be detected whereas with other detector

types, smoke has to migrate to, and be present in, the sensing area e.g. the

sensing beam of a beam detector or the sensing chamber of a point smoke

detector.

4. VSD, by providing accurate location of the incident, will

benefit applications where targeted fire protection measures are required.

5. The ability to have live video immediately available upon

detecting a pre-alarm or an alarm condition. This immediate situational

awareness allows monitoring personnel to easily view the protected area to

determine the extent of the fire and to more accurately identify the location.

6. Archiving of still and video images associated with alarm

conditions also provides a means of assessing the cause of incidents and

provides a basis for changes in the detection system if the event was a

false/nuisance alarm.

7. The ability to sub-divide the image into different areas

for separately identifying fire risks or programming out (masking) known

sources of potential false alarms.

8. VSD, by providing visual verification of the event, will

give operators information to facilitate a better and faster structured response

of an incident and enable safer investigation by remote viewing.

It is important to always follow the manufacturer’s

recommendations for testing, servicing, maintenance and replacement

requirements. It may be desirable that, in some installations where the effect

of potential false alarm sources cannot be fully determined, a period of trial

is undertaken before completing the commissioning of the system and handing it

over to the client.

A method, appropriate to the risk, of testing the

effectiveness of the VSD at both the commissioning stage and at subsequent

service and maintenance visits should be agreed with the equipment

manufacturers or system installer. Tests should be conducted and documented in accordance

with this method.

1. Where certain processes are likely to produce smoke-like

images which may be misunderstood by the video analysis software, unless it has

been demonstrated through trial and, if required, tuning of the equipment so

that the effect of these false alarm sources have been adequately established

and eradicated. Examples include processes generating large amounts of steam

and/or other gas plumes (exhaust fumes from forklift trucks) and/or

environmental pollutants (vapour, dust, sprays). In outdoor or semi-outdoor

situations this may also include insect swarms.

2. Where a deterministic response to known fires is required

and can be achieved by the use of EN 54 approved detectors, i.e. most standard

commercial and industrial applications.

3. Where there is a danger that the ambient lighting level

is either too low or too high to obtain a satisfactory response from the VSD at

the time it is required to monitor the risk, unless specific provisions are

available to alleviate this danger. For example infrared illumination of the

scene with back-up power supply, polarized lens filters, or where very intense

light sources can blind the camera.

4. Where there are significant obstructions in the camera

line-of-sight of the main identified risk or where such obstructions are

temporary and of an unpredictable nature.

5. Where a particular equipment configuration, including

installation cables, would not assure the integrity of the alarm transmission

path through the system so as to provide the desired warnings to the occupants

of a building or the desired response from the emergency services.

6. Where likely environmental conditions present may have an

adverse effect on the ability of the VSD to properly operate. For example this

would include fog, mist, snow and rain.

7. Where the use of

cameras is not appropriate due to data protection issues.