Risk Assessment & Quality Control Procedure For Access Control System

A security risk assessment plays a critical role in evaluating the vulnerabilities and potential risks associated with access control systems. Our expertise in premises security allows us to assist organizations in identifying, analyzing, and implementing effective security controls to safeguard their assets.

When conducting a risk assessment, several factors come into play, including the size of the organization, its growth rate, available resources, and the nature of its asset portfolio. By conducting a comprehensive security assessment, we help organizations identify their critical assets, assess potential risks, implement mitigating controls, and proactively prevent threats and vulnerabilities.

Industries such as healthcare, finance, and government have specific regulatory requirements, such as HIPAA, PCI-DSS, and Sarbanes-Oxley Audit Standard 5, that mandate security risk assessments. With our expertise, we can ensure that your organization complies with these regulations while enhancing the overall security of your access control systems.

Quality Control Procedure For Access Control System

1.0 SCOPE: .

This procedure applies to all

the inspection activities related to monitoring and measurement of products and

Processes related for the Installation or testing of subject activity where

applicable for the project and Applicable to:

·

Method Statement.

·

Quality Control Procedure.

·

Inspection and Test Plans.

·

Risk Assessments

·

FORMS.

2.0 PURPOSE:

The purpose of this procedure is to :

o

Identify processes /

products those are to be installed before using them in intended application.

o

Define the methods to

verify the quality of products and ensure that products that meet the stated

requirements are only used in the intended application.

o

Define the

responsibilities of concerned personnel related to quality control processes.

3.0 REFERENCES

Project Quality Plan

Material Approvals

4.0 DEFINITIONS:

PQP : Project

Quality Plan.

PSP : Project Safety Plan.

QCP : Quality Control Procedure.

HSE : Health, Safety and Environment

MS : Method Statement

ITP : Inspection Test Plan

QA/QC : Quality Assurance / Quality Control

Engineer.

SK : Store Keeper

WIR : Work Inspection Request

MIR : Material Inspection Request.

MAR : Material Approval Request

5.0

RESPONSIBILITIES:

5.1 Project Manager

- Project Manager is the overall

responsible for the project in terms of work execution, safety, planning &

quality. The Project Manager will maintain the planning progress and

coordination of works with the main contractor.

-

The work progress shall be carried out as per

planned program and all the equipment’s required to execute the works shall be

available and in good condition as per project planned.

-

Specific attention is paid to all safety measures

and quality control in coordination with Safety Engineer and QA/QC Engineer and

in line with PSP and PQP.

5.2 Construction Manager

-

Construction Manager is responsible to supervise

and control the work on site.

-

Coordinating with QA/QC Engineer and site Team

and foremen for all activities on site.

-

Control and sign all WIR’s before issuing to Consultant

approval.

5.3 Site Engineer

-

The method of statement to the system shall be

implemented according to the Consultant project specifications and approved

shop drawings.

-

Provision of all necessary information and

distribution of responsibilities to his Construction team.

-

The work progress shall be monitored in

accordance with the planned work program and he will provide reports to his

superiors.

-

The constant coordination with the Safety

Engineer to ensure that the works are carried out in safe working atmosphere.

-

The constant coordination with the QA/QC Engineer

for any works to be carried out and initiate for the Inspection for the

finished works.

-

He will ensure the implementation of any request

that might be raised by the Consultant.

-

Efficient daily progress shall be obtained for

all the equipment and manpower.

-

He will engage in the work and check the same

against the daily report received from the Foremen.

-

The passage of all the revised information to the

Foremen and ensure that it’s being carried out properly.

5.4 QA/QC Engineer (MEP):

-

The monitoring of executions of works at site and

should be as per the approved shop drawings and project specifications.

-

Ensure WIRs and MIRs are being raised for

activities in timely manner and inspected by the Consultant.

-

Check and insure that all activities / work done

/ completed prior to offer for consultant inspection.

-

He will follow and carried out all the relevant

tests as per project specifications.

-

Obtain the required clearance prior to Consultant’s

inspections.

-

Should acquire any necessary civil works

clearances and coordination.

-

Coordinate with site construction team.

-

One who will assist the Consultant Engineer /

Inspector during inspection.

5.5 Site Foreman

-

The carrying-out of work and the proper

distribution of all the available resources in coordination with the Site

Engineer on a daily basis.

-

Daily reports of the works are achieved and

coordinated for the future planning with the Site Engineer.

-

Incorporate all the QA/QC and Safety requirements

as requested by the concerned Engineer.

-

Meeting with any type of unforeseen incident or

requirement and reporting the same to the Site Engineer immediately.

5.6 Safety Officer

-

The implementation of all safety measures in

accordance with the HSE plan and that the whole work force is aware of its

proper implementation.

-

The implementation of safety measures is adequate

to maintain a safe working environment on the work activity.

-

Inspection of all the site activities and

training personnel in accident prevention and its proper reporting to the

Construction Manager and the Project Manager.

-

The site is maintained in a clean and tidy

manner.

-

Ensure only trained persons shall operate the

power tools.

-

Ensure all concerned personals shall use PPE and

all other items as required.

-

Ensure adequate lighting is provided in the

working area at night time.

-

Ensure high risk elevated areas are provided are

barricade, tape, safety nets and provided with ladders.

-

Ensure service area/inspection area openings are

provided with barricade, tape, and safety nets.

- Ensure safe access to site work at all times.

5.8 Store Keeper (SK)

- Responsible

for overall Store operations in making sure to store the material delivery to

the site and keep it in suitable area that will keep the material in safe from

rusty and damage.

- One who will

acknowledge the receiving of materials at site in coordination with QA/QC and

concerned Engineer.

5.9 Emergency Absents

-

If QA/QC not available the adequate QA/QC Engineer

will be responsible for quality control activities.

-

If the P.M. not available the Construcion manager

will be resposible for all of his activities.

-

If the HSE Engineer not available the adequate HSE

Engineer are resposible for safety activities.

-

If Engineer not available Construction manager will

assign his duties to the concerned supervisor, forman or alternate Engineer.

-

Replacing staff, in case of absent, with another

designation can be accepted only for a minimum period of days absent otherwise

the Contractor shall replace the relevant person with same designation which

required approval from CONSULTANT.

6.0 PROCEDURE:

-

Check that all the following documentations have

been approved by the Consultant to proceed with the installation activities:

· Quality

Control Procedure

· Method

Statement

· Inspection

Test Plan

· Check List

· Risk

Assessment

· Shop Drawing

Submittals related to work

-

Check all the delivered materials are inspected

and approved by the Consultant’s Engineer.

-

Ensure that the respective work area has been

cleared by previous trades for start-up installing the system.

-

Ensure that the installation of the material is

as per approved shop drawings, approved method statement, Manufacturer’s

recommendation, and prevailing quality standards.

-

Ensure the following checks are performed during

the installation progress:

-

Check all materials are as per approved submittal.

-

Check all Material are installed as per approved

shop drawings.

-

Check if coordinated with other services.

-

Check installation if it is carried out as per

approved method statement.

-

Check that the system checked and approved by Consultant.

-

Ensure WIRs are issued on time without delay.

(Min. 24 Hours notice for site inspection).

-

Ensure all inspection is performed as per

approved Inspection Test Plan.

- Check ITP, Check List, WIR, and NCR (if any) are signed off and cleared by the Consultant Engineer.

7.0 ATTACHMENTS

7.1 Method Statement

7.2 Inspection and Testing Plan

7.3 Check List for Installations

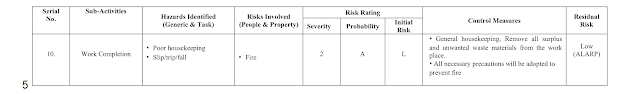

7.4 Risk Assessment

7.5 Attachments:

7.5.1 Manufacturer recommendations.

7.5.2 Emergency Evacuation Plan.

7.5.3 Technical Details.

2 comments:

This Barricade tape manufacturer in India is highly durable and highly visible, perfect for marking off areas for safety or construction zones. The bright color ensures high visibility, even in low light, making it an essential tool for keeping work areas secure. Easy to use and weather-resistant!

I appreciate how this blog maintains a positive, forward-thinking tone throughout. The advice here encourages growth and learning. The best part is that it’s genuinely helpful. Entrepreneurs implementing these ideas could benefit greatly from rental office space in Bangalore.

Post a Comment